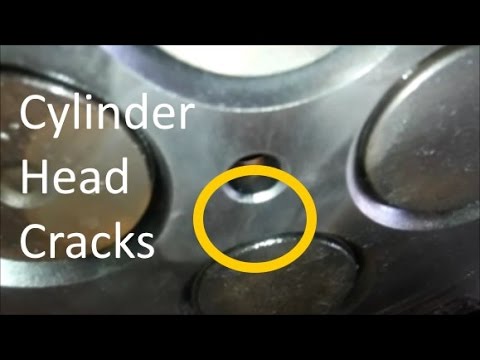

The cylinder head is a crucial part of all combustion engines, and cylinder head cracking can result in catastrophic damage to the engine. In some cases, cracking may result in such severe injury to the engine that it must be replaced. As a result, most motorists try to prevent cylinder head cracking, as an ounce of prevention in this case is worth many pounds of cure. The causes of cracking are all relatively simple and easy to prevent, except in the case of mechanical parts failure through no fault of the operator.

The cylinder head, used in combination with a head gasket, seals the cylinders of the car, along with other parts associated with them. The cylinder head is customized for the vehicle, and has very precisely milled surfaces to provide a smooth and flush fit with all connecting parts. In the case of a minor crack, the cylinders may lose compression and misfire. Major cracks can cause severe damage to the cylinders of the engine. For this reason, when replacing either the cylinder head or the head gasket, make sure that you are using the correct parts, including bolts, for the job.

The constant change in temperature causes cracks to form in aluminum heads. Cracking causes the head to lose pressure, resulting in lost power for your vehicle. When performing your own check for cracks, you need a method of testing that does not use expensive equipment and works with a non-magnetic metal. Performing a dye penetration test makes the smallest cracks easily visible without the need for expensive equipment or a special testing facility.

Step 1

Clean the aluminum head. Wipe the aluminum head with a clean rag to remove large dirt and accumulated oil. Spray cleaner-remover from a three-part dye penetrant test kit onto a clean rag. Wipe all surfaces of the head with the dampened rag.

But if you have cast iron heads then cracks will form eventually. The common causes. A big reason why cracks form on the cylinder heads is because the valve seats become hardened from the concentrated heating process. This ends up putting more stress on the cylinder heads, causing them to crack after awhile. The best way to preserve the life of your cylinder heads is to keep your radiator filled and make sure you have no stretches hoses or leaky belts. If your car ever overheats then have your head gaskets replaced and the heads checked or cracks.

Step 2

Shake a can of penetrating dye for 30 seconds. Spray the penetrating dye on all surfaces of the aluminum head. Allow the dye to sit on the head for five minutes.

Step 3

Wipe the dye from the aluminum head with a clean rag. Spray the cleaner-remover directly onto the aluminum head and immediately wipe the head with a clean rag to remove all traces of penetrating dye.

Step 4

Shake a can of developer for 30 seconds. Hold the tip of the spray can 6 inches from the aluminum head. Move the spray can as you spray the developer onto the head. Allow the developer to sit for 30 seconds to one minute.

Step 5

Cylinder Head Check For Cracks In Car

Inspect the head for cracks and pits. Look at each part of the head for lines or spots that match the dye color. A line designates a crack, and a spot designates a pit or other small imperfection on the aluminum head. No lines or spots designate an aluminum head free of defects.

Remove the developer from the aluminum head with a clean rag and the cleaner-remover supplied with the three-part dye penetrant test kit.

Items you will need

- Clean rags

- Three-part dye penetrant test kit

Cylinder Head Check For Cracks

- Jupiterimages/Photos.com/Getty Images